WHMS WreckingBots 2.0 Considerations and Build

WreckingBots 2.0

WreckingBots is a game where robots wreck the tower of

cubes, drop the opponent's cubes into the corner bin and push the opponent's' base

switch to decrease the opponent's' life {by point system). Robots should be

built in a way that it survives the 5-minute game of physical contact with

other robots.

Playing Field

1. The playing

field is 16' x 16' in size.

2. Each base has

an area of 3 feet square.

3. The ball

switch has about 1' clearance from the ground.

4. The ramp

incline is about 26 degrees.

5. There are 20

blocks in total (10 blocks for each team)

Robot Specifications

1. The maximum size

of the robot is 3' x 3' (length and width) and must fit in the base.

2. Weight and

height are unlimited.

Not Allowed

1. Chemical or

liquid

2. Fire or

flammable materials

3. Rope, strings,

or similar materials to damage robot operations

4. EMP generators

5. Signal jammers

6. Blades

7. Projectiles

8. Explosives

9. Guns

10. Sticky

materials

General Rules

1. Robots may be

autonomous or remotely controlled.

2. Failure to

show at the playing area 2 minutes after the scheduled time will cause the team to

forfeit the game.

3. Judges

decision is final.

4. The referee

may recall teams for a tiebreaker round if needed.

Rules

1. All robots

will have 100 life points at the

beginning of the game with a designated color of block and base.

2. Robot's life

diminishes depending on the color of the block dropped completely into any of

the crates by any robot. Each block dropped is equivalent to –5 life points.

3. If the switch

of a base is tripped once (indicated by a solid light), the robot of that base

may Jose 20 life points. It can be

switched back to regain life points.

4. If the switch

of a base is tripped again (indicated by blinking light), the robot of that

base may lose 30 life points. It can

be switched back to regain life points.

5. There will be

at least a 15-minute break between elimination and final rounds to enable winners

to fix their robots and have it inspected again.

6. The robot that

has the most life points at the end of a 5-minute elimination match wins the

game and advances to the final match.

7. Scores will

reset in the final round.

8. Once a robot

is immobile, damaged beyond repair, or thrown out of the playing field, it will

be considered a "knockout" and the other robot wins regardless of

points.

property of robotnook.com

©2015 Mario Malabunga. All

rights reserved.

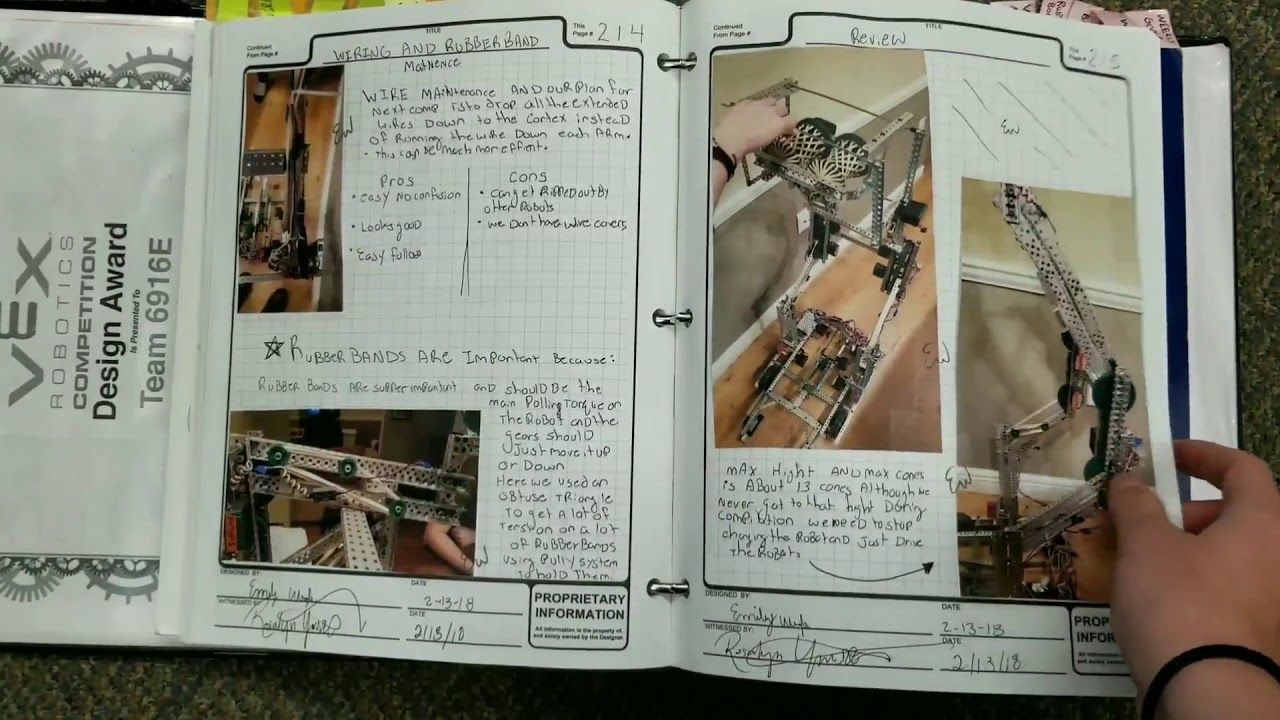

These are the published rules for the competition

build. In order to determine the best

build, we have to break the competition into tasks.

1. No larger than 3x3 ft and fit in the Base.

2. Be

able to pick up blocks and transport them up the ramp and into the basket.

3. Move the ball switch back and forward.

4. Be

able to drive up a 26-degree slope.

5. Be

tall enough to not get stuck on blocks (2").

6. Be

robust enough to not be wrecked by the opponent’s bot.

Now let’s talk about build considerations:

1. If

gearing is an option, consider it.

2. Have

an articulated arm and be able to move it vertically, and horizontally in 3D.

3. Last

year there were several bots that high centered on blocks, effectively

immobilizing them for the entire match.

Make the suspension high enough to drive over blocks and up the ramp.

4. If

the frame is higher, it needs to be wider to prevent being pushed or tipped

over because the articulated arm must operate at an average height of 1 ft off

the ground.

5. Articulated

arm can be dual purpose…tripping the ball switch and picking up blocks.

6. Last

year, the WHMS WreckingBot fell apart on the field. Consider using nuts with nylon inserts to

prevent them from falling apart under duress.

7. Several

bots last year lost their sync with the controller. Harden the connections and controllers to

ensure it maintains sync. You can’t

touch it after it starts.

I will add more as time permits, including photos.